For a while now, the world has been changing at an accelerated pace and we believe that is a chance for us to reinvent ourselves. From the start, our brand was founded from an everyday problem for us as cyclists, and when this idea was materialized, we were able to notice that this was something beyond our borders. Since then, we have been able to help people from all over the world who have bet on storing their bikes in our furniture.

Today, in collaboration with the University of Chile’s FabLab, we resolved to go for another way to reach to our customers around the world, which considers the use of new fabrication technologies and global nets of creators. This model is called Distributed Design, which has been promoted by FabLabs around the globe and until now put into practice in the furniture market by the British brand Opendesk, and looks to contribute to a circle economy based future, opposed to the way production is today, in a linear and centralized way.

Traditional business within the furniture industry often implies supply chains and business models that lead to enormous retail mark-ups, competitive production costs and therefore its associated workload, and little or no materials traceability and sustainability.

The design of a product for mass fabrication generally comes from an external source, where the materials and production costs are lower (often involving countries where land and labour costs are the cheapest, like China). For the production of these products, the pieces are obtained from factories and delivered to centralized assembly lines, then this finished products are sent to the other side of the world in containers. These items are then stored in large regional warehouses, before being finally delivered to customers or retail outlets. This kind of process is the type to squeeze makers and designers, generating considerable profit for the middlemen and even a greater carbon footprint.

Our approach to Distribution Design

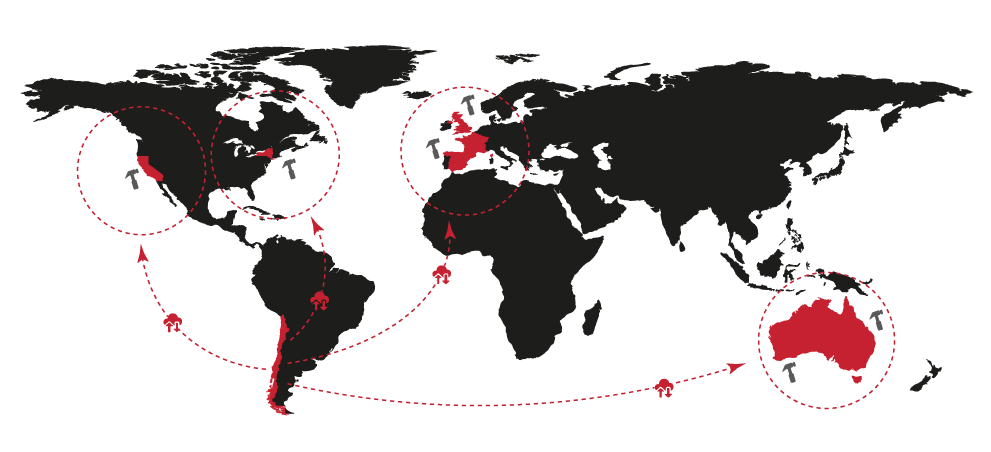

Until 2019, in Chol1 our products were designed and manufactured in Chile, to be then sent to their destinations across the world by air mail. This implicated long periods of delivery and large shipping costs, in addition to an enormous carbon footprint caused by airplane transportation.

Distributed Design is a production model that allows to fabricate objects at a long distance with local makers, thanks to digital fabrication technologies.

Along with the implementation of this model, Chol1 products are designed in Chile and manufactured in different location around the world by local makers. This seeks to reduce the delivery radius (implying its costs and associated delivery time), and for products to be made using local materials.

An alternative model

Independent manufacturers are at the center of this model, and paying a fair price to people who manufacture furniture from Chol1 is very important to us.

This generally means that a greater amount of the sale price goes to the manufacturer compared to traditional factory production, which may depend on large volumes of stocks made for low or minimum wages.

Our model saves in shipping (which is a lot since, from Chile, any shipping to the USA or Europe travels more than 8000 km), storing, and exhibition rooms.

Instead, this money goes mainly to the makers, and to build, administer and commercialize the necessary technical infrastructure for the creation of a global furniture market.

When you buy furniture in Chol1, you’re supporting local makers, supporting our designers, and making a future for distributed fabrication to be possible.

We love to talk to our community about this model and why we work this way. If you have any question, thought or idea, don’t hesitate to contact us!